67kW – 1900kW: Ultra-reliable Air Cooled & Water Cooled inverter driven screw compressor chillers. The G Range delivers precision chilled water temperature control at design temp. +/- 0.5oC.

This extensive range of Water Cooled chillers & Air Cooled chillers includes models with Adiabatic & Free Cooling systems & a Condenserless chiller option for use with remote condenser also.

Designed with few moving parts, vibrations & associated noise are minimised, wear & opportunities for failure are greatly reduced along with on-going maintenance costs. They are ideal for industrial cooling systems & specialist HVAC environments including data centres.

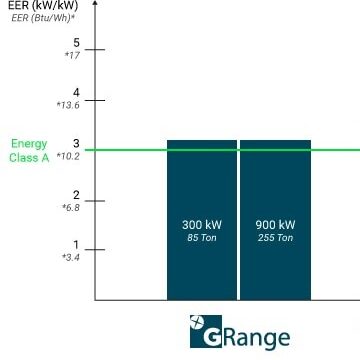

G Range chillers are typically Energy Class A rated (unless specified for custom applications) under EU Ecodesign Energy-Related Products & Energy Information Regulations 2021 with excellent EERs.

G Range offers two lines across all models each running different classes of refrigerant to accommodate customer priorities in terms of efficiency & environmental sustainability:-

ENERGYMISER: optimised for energy efficiency using HFC refrigerant R134a.

GREENMISER: optimised for use with very low GWP (Global Warming Potential) refrigerants HFO-1234ze & R290.

All units supplied completely wired, connection ready & equipped with proprietary, panel mounted Geotouch™ touchscreen programming & monitoring system. With strong metal structures each unit is painted with epoxy powder & anti-rust coating as standard.

Smart Chiller Technologies

Remote monitoring, diagnostics & programming is available via the Onboard Touch™ web-based solution. From anywhere in the world the Geoclima engineering team, and approved trained on-site engineers, can analyse all chiller activity including voltage swings, that may affect performance, and fix problems to ensure optimal performance at all times.

For environments sensitive to noise, the smart Dynamic Noise Control (DNC) system constantly measures chiller noise & "adapts" performance within permissible ranges & programmable time-slots.

The G Range provides significant scope for customisation enabling precise configuration of each model optimising for specific applications, operating conditions & priorities. Options include custom dimensions, galvanised frames with hersite coils, low speed fans & compressor sound insulation kits - Low noise (LN) or super low noise (LLN), low temp chilled water/glycol to -3°C, extreme climate operation adaptions (-40°C & +40°C), pump pressurisation units & expansion vessels, construction for explosive environments.

Click here to contact our Technical Sales Team.

GHA: 68kW - 1800kW

Air cooled chillers- screw compressors - dry expansion evaporator - ENERGYMISER & GREENMISER lines - EC axial fans

GHA ES: 75kW - 1900kW

Air cooled chillers- Adiabatic system - screw compressors - dry expansion evaporator - ENERGYMISER & GREENMISER lines - EC axial fans

GHA FC: 68kW - 1700kW

Air cooled chillers - free cooling system - screw compressors - dry expansion evaporator - ENERGYMISER & GREENMISER -EC axial fans

GHH: 68kW - 1850kW

Water cooled chillers - screw compressors - dry expansion evaporator - ENERGYMISER & GREENMISER lines.

GSE: 67kW - 1900kW

Condenserless unit - indoor install - for use with remote condenser - screw compressors - dry expansion evaporators - ENERGYMISER & GREENMISER lines.

GSA: 68kW - 1800kW

Remote condenser - for use with GSE condenserless chiller - Air Cooled - screw compressors - EC axial fans